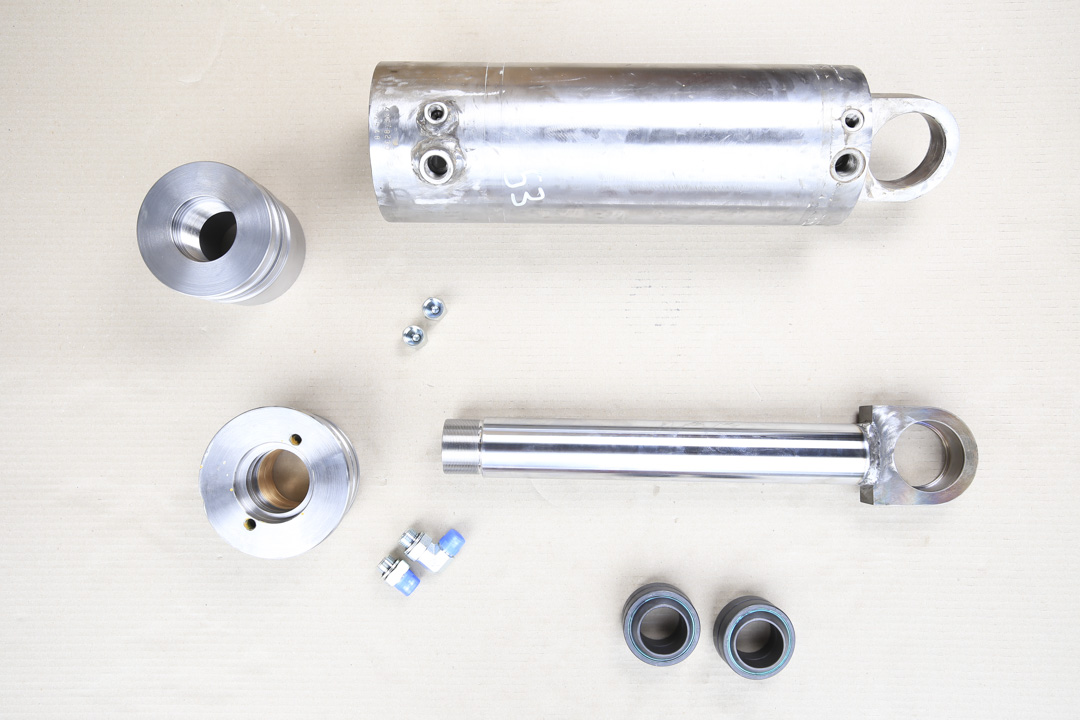

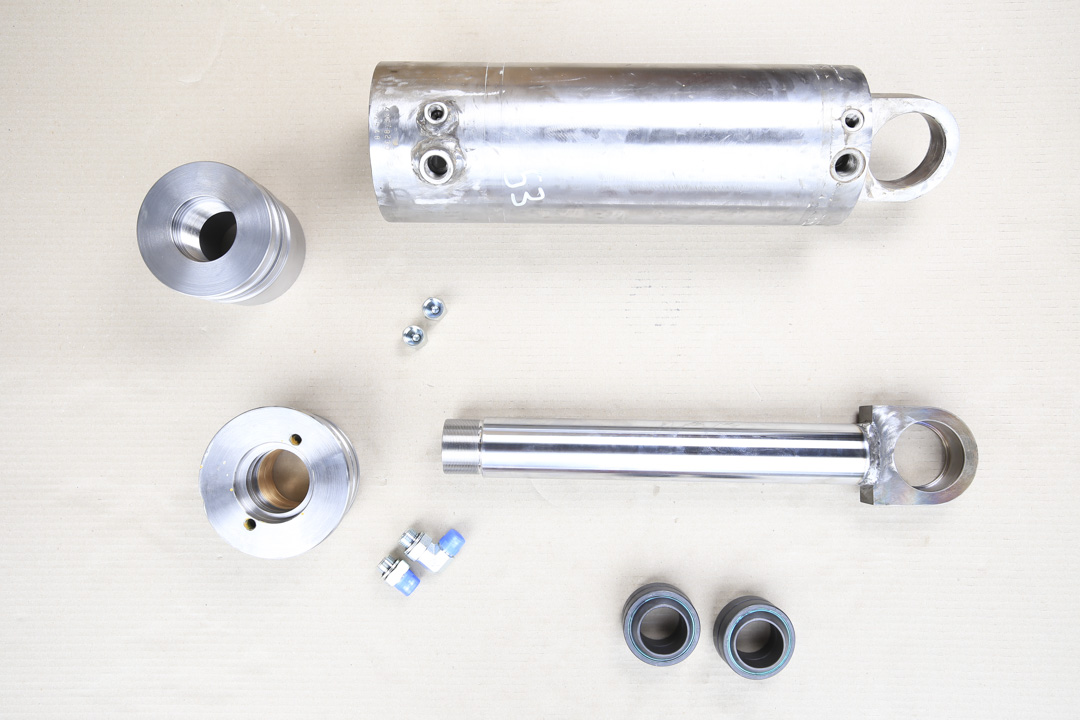

Hydraulic Cylinder Repairs & Maintenance

Queensland Hydraulics design and manufacture hydraulic cylinders, so repairing them back to new is effortless. We possess the right machinery, tools, people and knowledge to repair any hydraulic cylinder and our attention to detail is what sets us apart from the others. Our services include:

- Completing an FEA (Finite Element Analysis) and engineering calculations to identify a cylinder’s stress points and confirm its suitability and sustainability to the tasks it is undertaking

- Measuring the surface finish on all cylinder barrels and piston rods

- Measuring all seal grooves to ensure they comply to Manufacturer’s tolerances

- Gauging and measuring chrome thickness to check that it achieves a minimum 25 micron or meets customer specification

- Via Micrometers, we measure the diameter of rods and bush glands accurately to ensure working tolerances meet industry standards

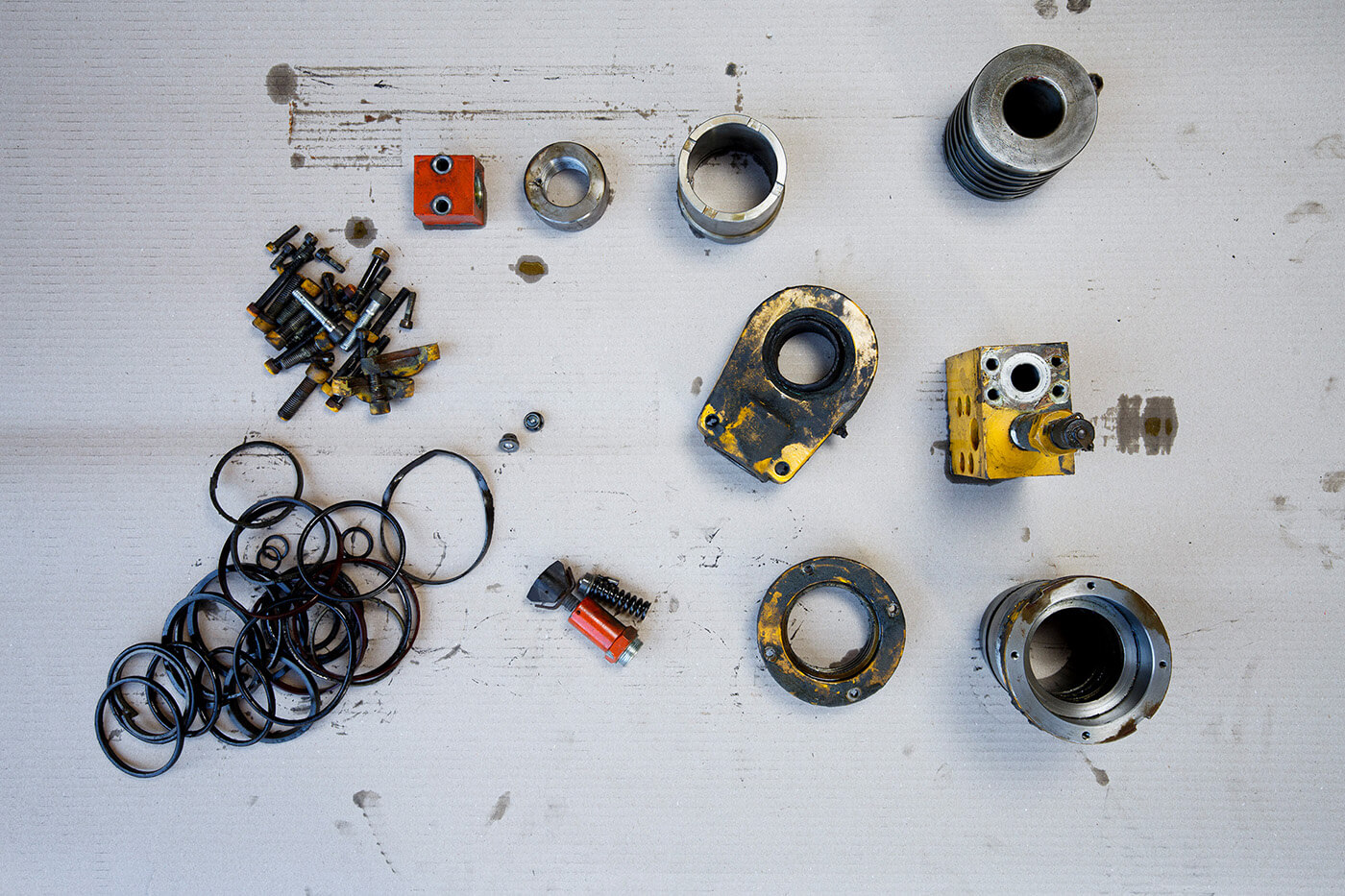

- Paint stripping, rustproofing and finishing with two epoxy coats on all cylinders

- Abrading by hand (rather than sandblasting, which has the potential to damage components of the cylinder)

- We aim for a 4:1 in our own designed cylinders, so before pressure testing we calculate the safety factor on all repairs

- Providing a test certificates on all of our repairs

It’s thorough, its unrivalled!

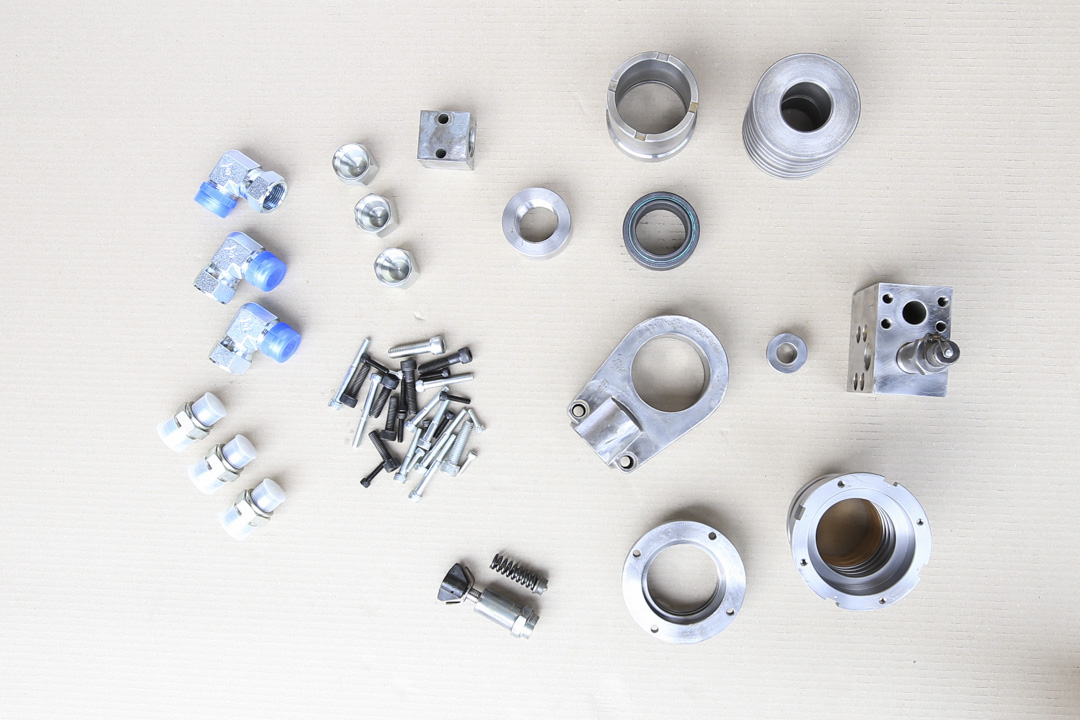

Quality

Our 40 years of business and reputation has been built around our company motto “Success Through Quality” and this is validated by Our ISO9001:2015 Quality Management System. It is third party audited annually and extends throughout our organisation including our repair and maintenance service.

Expertise

As an Engineer and manufacturer of our own proprietary hydraulic cylinder range we are suitably qualified to repair any hydraulic cylinder. We have the right machinery, tools, people and knowledge. We are engineers and capable of completing an FEA (Finite Element Analysis) and engineering calculations to identify a cylinder’s stress points and confirm its suitability and sustainability to the tasks it is undertaking.

Transparency

For those companies that have stringent Quality Control processes and requirements, you’ll be impressed with our repair service offering. We can provide you with inspection reports once we’ve disassembled and inspected your cylinder outlining our findings, our repair recommendations and itemising all facets of proposed work along with the respective costs.

Reliability

A critical piece to your repair puzzle is partnering with an organisation that understands and is responsive to your needs. We are small enough to be agile and flexible and capable of meeting the demands customers place on us, yet big enough to have ISO 9001:2015 Quality Management Systems in place to ensure a quality product and service each and every time.

Experience

With over 180 years of collective experience in the hydraulics industry, and in our humble opinion, you’d be hard pressed to find a more knowledgeable and dedicated supplier.

Our solutions and products are proven and have stood the test of time and all our staff are suitably qualified in professionally handling your hydraulic matters.